|

| April 09, 2013 | Volume 09 Issue 14 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

All about the latest, ultra-precise hexapods

By Jim McMahon

In the past several years, with the integration of advances in technologies like piezo actuators, virtual programmable pivot points, and system simulation, hexapod performance has taken a significant leap forward, to the extent that electromechanical and piezoelectric hexapods are now viewed as more efficient and accurate systems compared to serial linkage and hydraulic kinematic positioning systems, including those commonly used on robotic arms. The latest versions of hexapods are capable of delivering unprecedented ultra-precision resolution to as low as 0.03 microns (33 nm) of incremental motion, and some can provide velocity of several 10 mm/s, making them a preferred robotics system for industrial testing and positioning, microscopy, semiconductor handling, biotechnology, and medical applications (Figures 1 and 2).

Figure 1 (left): Hexapod surgical robot with endoscope and phantom. [Courtesy: Fraunhofer-Institute for Production Technology and Automation (IPA)]. Figure 2 (right): Hexapod for ALMA (Atacama Large Millimeter Array) telescope.

Hexapods

A hexapod, also known as a Stewart platform or Gough/Stewart platform, is a six-legged parallel mechanism structure. In it most common form, it consists of two platforms, one fixed and the other movable, which are connected and supported by six actuator legs (struts) that expand and contract, acting in parallel between them. Coordinated motion of these six struts enables the movable platform, and devices mounted to it, to move in any direction, operating with six degrees of freedom (DOF) relative to the other base platform. With six DOF, the movable platform is capable of moving in the three linear directions of x, y, z (lateral, longitudinal, and vertical) and the three angular directions (pitch, roll and yaw) singularly or in any combination. Because hexapods have all six degrees of freedom, they can perform manipulations that cannot be done with any other traditional motion system.

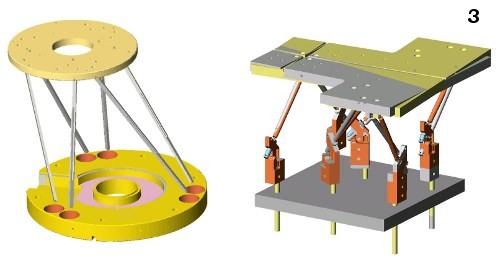

In addition to the variable-strut-length hexapod of the Gough/Stewart flavor, other designs with fixed-strut length are also available (Figure 3).

Figure 3: Comparison of variable-strut-length hexapod design to fixed-strut-length design (platform shown in two positions). This fixed-strut-length hexapod uses six linear modules to move the basis of each joint up and down. Other designs that move the joints in one plane are also available.

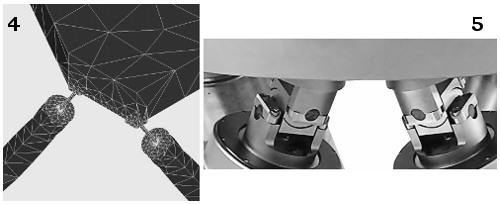

Most hexapod struts are equipped with cardanic joints. Flexure joints provide the highest precision and are completely free of backlash (Figure 4). However, load capacity and travel range are rather small compared to cardanic or sphere joints. Cardanic joints with Z-offset provide the best load characteristics (Figure 5). These joints are much stiffer than gimbal-type joints, however they require more sophisticated control algorithms to take into account the complex geometry of each actuator.

Figure 4 (left): Hexapod flexure joint design. Figure 5: Cardanic joints with Z-offset provide the best load characteristics.

Hexapods come in many configurations and sizes, capable of handling loads from a few pounds to more than 2 tons (Figure 6). Advanced designs include servo-motor-driven systems for moving large optics or mirrors, piezo-based units for nanometer precision control of processes, and non-magnetic and vacuum-compatible versions. While most hexapods have a cylindrical shape, square or rectangular versions have also been used (Figure 7).

Figure 6 (left): High-load hexapod. Load capacity >1 ton, sub-micron resolution. Figure 7: Square hexapod with large aperture.

Hexapods have a tremendous potential for streamlining many manufacturing processes by improving accuracy and speed, and reducing set-up and processing time.

Benefits of hexapods vs. serial kinematic positioning systems

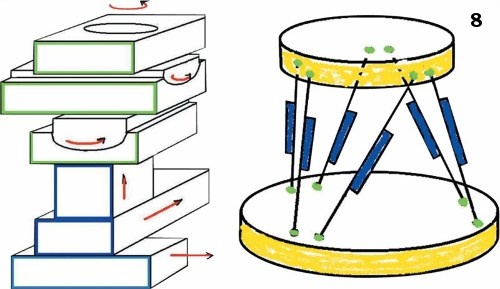

Parallel-kinematic mechanism (PKM) motion systems have a number of advantages over standard serial kinematic (stacked) positioning systems (Figure 8). It is easy to see most benefits by just looking at the basic designs.

Figure 8: Six-axis positioners. Serial kinematics (stack of six stages, left) compared to parallel kinematics (hexapod, right).

a) Elimination of cumulative error. In serial kinematic positioning systems, wobble and guiding errors in the bearings of each axis accumulate; the bottom stage supports its own moving platform plus all stages above it. Each actuator is assigned to one degree of freedom. Integrated position sensors assigned to each drive measure only the motion caused by that drive and in its direction of motion. All undesired motion (guiding error) in the other five degrees of freedom is not seen and therefore cannot be corrected in the servo-loop, which leads to cumulative error.

b) Less deviation. In a hexapod, all actuators act directly on the same moving platform, with the same dynamic behavior occurring for the six axes. Because each actuator basically only has one degree of freedom (unlike a serial stack of stages, where the bearings in each axis also contribute to crosstalk and runout), runout and accumulation of off-axis errors is much less of a concern for hexapod designs. A hexapod can also be designed much stiffer, so load-shift-induced flex is far less of an issue. The results are significantly reduced deviation and improved repeatability.

c) Automatic strut compensation for velocity and vector. As different from serial multi-axis positioning, hexapods require that all six struts alter their lengths if a change in only one axis is intended to occur. However, this is completely transparent to the user. The hexapod controller automatically runs the required coordinate transformations directing individual velocity and vector adjustments and transmits new positions to each of the six actuators hundreds of times per second.

d) One-third the parts for lighter weight, lower friction, and higher reliability. Compared with serial multi-axes systems, hexapods have one-third the number of parts, which means lighter weight and lower friction. Friction and torque in serial systems, caused by as many as five moving cables (cable management), limit accuracy and repeatability.

e) Reduced settling times. Because of the low mass of the moving platform on hexapods, positioning operations can be performed with far lower settling times than with conventional, stacked multi-axis systems.

f) High nominal load-to-weight ratio. The high nominal load-to-weight ratio is a very important advantage of the hexapod over stacked systems. The weight of a load in the hexapod platform is approximately equally distributed on the six parallel legs. This means each link carries only one-sixth of the total weight. Additionally, under certain loads the legs on the hexapod act longitudinally, exerting either tension or compression on the struts and reducing axial forces.

g) Free access to the work zone. Hexapods allow free access to the work zone. There is nothing to impede the motion of the machining tool in the workplace.

h) Large, central aperture. This is critical for optical applications, thru-light applications, or access to the back of a workpiece.

New features support sub-micron ultra-precision

The latest high-resolution hexapod systems are being designed with high-efficiency, precision-controlled servo-motors and piezoelectric actuators. Different drive principles are being employed, depending on the application.

For example, new hexapods utilizing NEXLINER piezoelectric drives from Physik Instrumente, a leading industry manufacturer of both ultra-precision hexapods and piezoelectric motors, make for a positioning device that is completely non-magnetic. Such a system is critical for medical equipment and device applications that require magnetic non-interference. Other uses include high-energy physics applications (Figure 9).

Figure 9: Non-magnetic, high-load piezo-ceramic-motor hexapod.

In addition to classical hexapod structures, parallel-kinematic designs are also beneficial to sub-nanometer precise positioning mechanisms, required for AFM (atomic force microscopy) applications and other novel super-resolution microscopy systems. With the integration of non-contact capacitive sensors, run-out errors on a nanometer and sub-nanometer scale can be determined. The sensors continually measure the actual position against the stationary external reference, and a servo-controller can compensate the error in real time (active trajectory control). Resolution and repeatability can attain 0.1 nanometer in such systems.

Recent hexapod designs provide extremely high stiffness and rigidity of their components and all moving parts, such as its bearings, joints, and drive screws. This results in high natural frequencies (500 Hz at a 22 lb load) that prevent bending in the six struts or in the movable platform, making these new hexapods capable of extreme accuracy and an ideal tool for precision machining, metrology, microscopy, and medical applications.

One such system is the new miniature six-axes hexapod, Parallel Kinematics Hexapod Nano-Alignment System (Figure 10), again from Physik Instrumente, which can deliver more than 10 lb of force and motion in all six degrees of freedom. Minimum incremental motion (real-world motion) is as low as 0.2 microns with actuator resolution of 40 nm and travel ranges to 40 mm linear and 60 degree (rotation), and a velocity of 10 mm/s. This unit can be used for manufacturing and part placement, alignment of optical components and lasers, microscopy applications, and neuroscience that requires high precision. A higher-resolution version (33 nm) with reduced load is also available.

Figure 10: Miniature hexapod.

The system's high level of accuracy is a combination of extremely precise parts, precision assembly and testing, and sophisticated algorithms built into its high-speed controller that take into account the exact tolerances of each strut and joint, and provide precise coordinates to each of the six actuators.

Hexapods require the definition of a fixed pivot point as the center of rotation. Advanced hexapod designs make use of a virtual, programmable pivot point for rotational alignment tasks, allowing motion around any point, not unlike the human hand.

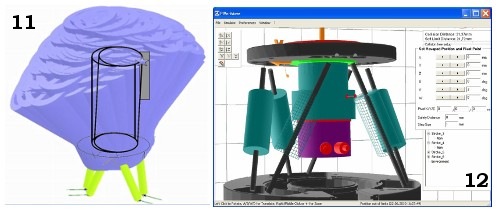

Because of the complex motion a hexapod can perform (Figure 11), it is desirable to have simulation tools to explore the possible motion range of the payload mounted to the hexapod. Figure 12 shows a simulation tool with automatic collision detection/avoidance. The shape and size of the payload can be added by the user inside or outside the hexapod envelope, and the software calculates the distance to any obstacle in its way.

Figure 11 (left): Work space of hexapod with a cylindrical payload. Figure 12: Hexapod working space simulation tool with automatic collision detection/avoidance.

The latest PC-based digital controllers, facilitated by open-interface architecture providing a variety of high-level commands, allow choosing any point in space as the pivot point for the rotation axes by software command.

Target positions in six-space are specified in Cartesian coordinates, and the controller transforms them into the required motion vectors for the individual actuator drives. Any position and any orientation can be entered directly, and the specified target will be reached by a smooth vector motion. The pivot point then remains fixed relative to the platform.

In addition to the coordinated output of the six hexapod axes, these new hexapod controllers provide two additional axes that can be used to operate rotary stages, linear stages, or linear actuators. Some include a macro language for programming and storing command sequences.

These controllers feature flexible interfaces, such as TCP/IP interface for remote, network, and Internet connection.

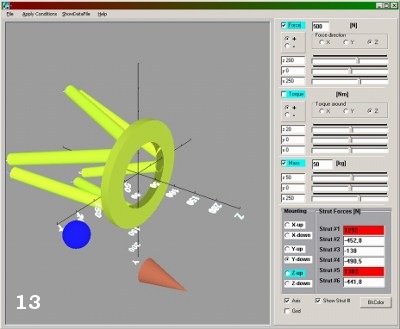

New simulation tools are being incorporated for graphical configuration and simulation of hexapods to verify workspace requirements and loads (Figure 13). Such software provides full functionality for creation, modeling, simulation, rendering, and playback of hexapod configurations to predict and avoid interference with possible obstacles in the workspace.

Figure 13: Hexapod strut force calculation tool.

With the new design developments that hexapod systems are experiencing, manufacturers and researchers that have a need for extreme high resolutions and high accuracy can now capitalize on them for improvements within their workplace.

Hexapod technology has advanced considerably in a few short years, so now it is up to industry to embrace these new developments and put them to work to reduce set-up and processing time, overall production cycle times, and ultimately reduced cost of operation.

About the author

Jim McMahon writes on instrumentation technology. His stories have been carried in hundreds of trade publications worldwide and are read by more than five million readers monthly. He can be reached at jim.mcmahon@zebracom.net.

Want more information? Click below.

Published April 2013

Rate this article

View our terms of use and privacy policy